20

Mar

2013

Millers Oils Nanodrive (NT) Motorsport Engine Oils

In January 2012 at Autosport International exhibition Millers Oils launched a new generation Nanodrive (NT) range of “ultra low friction” engine oils for motorsport-highly tuned car applications. Nanodrive (NT) range motorsport engine oils available in the following viscosities: 0w20, 0w30, 5w40, 10w40 and 10w60.

Nanodrive (NT) engine oils represents a new generation of engine oils for modern race engines providing enhanced performance needed to compete at the highest levels in motorsport.

Nanotechnology additives in engine oils

Normaly high quality synthetic engine oils contain the following additives in addition to good quality base oils:

- E.P. (Extreme Pressure) additives which enables engine oil to retain it‘s properties under severe loads/pressures.

- A.W. (Antiwear) additives which improves protection of metal surfaces against wear, this ussually called ZDDP – that contains correct amounts of Zinc.

- Pour Point Reduction additives – enables to maintain oil flow properies under sub zero temperatures.

- Viscosity Modiiers – additives improving oil viscosities.

In an internal combustion engine, it is estimated that 15-20% of energy is lost through internal friction.

Millers Oils developed technolgy enabling to use nano additives in addition to above listed oil additives used in conventional oils.

Nano particles have a very high surface area to volume ratio. As a result, higher percentage o atoms can interact with other matter, leading to an increase to reactivity. Nanotechnology allows combination of molecules to be designed with unique properties that are superior to larger particles of the same component.

The definition of Nano

1A nano particle is the same scale as to a football as….

…. a football is to the earth.

Nano: the SI prefix meaning 10¯⁹.

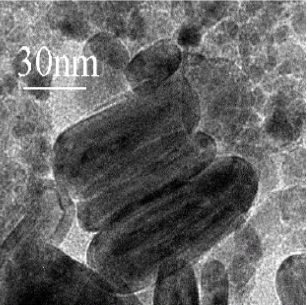

Typical nano particle construction

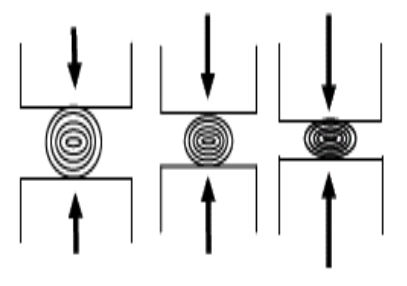

One of the main Nano additives properties (used in Millers Oils Nanodrive oils) is Nano particles behaviour under increased pressure/loads. Under these severe conditions Nano particles due to their exlusive construction starts changing shape, rather than being pulled out from surfaces or destroyed-consumed (See graphical representation below), therefore preventing direct contact between 2 metal surfaces.

Another exclusive property of Nano particles used in Millers Oils oils is their behaviour under increased shear loads. Due to Nano particles construction (multilayers) they easealy adapt to microscopic gaps between 2 moving surfaces. When shear load increases, rather than being pulled away or destroeyd, these Nano particles start loosing layers gradually forming protective coating/film between 2 moving surfaces (See graphical representation below).

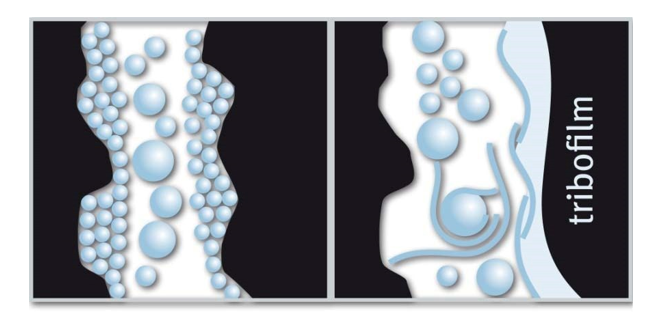

Figure below shows action of nanoparticles in lubricant on microscopic scale, where interacting mettalic surfaces are not smooth, but contain asperites. When these asperities come into contactr with each other heat and wear increased, sometimes leading to mechanical failure. Now imagine the nanoparticles as billions of ball bearings which fill the gaps between moving parts, sticking to the surfaces to even out peaks and troughs. These nanoparticles are referred to as „ nested spheres“ as they are similar to onion-like structures, having ability to exfoliate under high pressure and can shed an outer layer which orms a protective film or triboilm on the metal surfaces. The ilm then protects the metallic parts under static and dynamic conditions and reduces riction and wear. The film will remain intact even during oil changes.

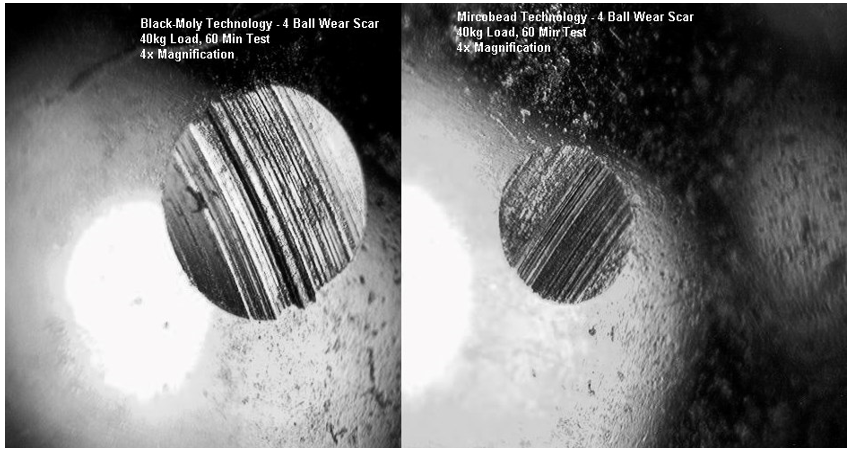

4 Ball Wear Scar Test

One of the standard oil/grease tests used in oil industry is called 4 Ball Wear Scar Test which is undertaken according to ASTM D 2266 and ASTM D 2596 standards/conditions.

Bellow pictures indicating the extent of wear occurred on steel balls using conventional oil and oil with Nano additives. Pictures are 4X magnification. It is clear that extent of wear on the steel ball using conventional oil (picture on the left) is much more greater than on the steel ball using oil with Nano additive. In general Nano additives achieved up to 80% reduction in metal removing.6

High Frequency Reciprocating Rig HFRR test

Millers Oils undertook HFRR tests using conventional Ford M2C 913C 5w30 (ACEA A5/B5) synthetic oil and second test using the same oil, but with added Nano additives.

Ford M2C 913C 5w30 standard oil ACEA A5/B5

Red line represents oil temperature increase

Green figures above graph represent oil film strenght

Blue figures above graph represent friction coeficient

Modified Version – friction reduced by 50% & stronger oil film

Red line represents oil temperature increase

Green figures above graph represent oil film strenght

Blue figures above graph represent friction coeficient

It is clear rom the above tests results, oil with Nano additives has much more greater properties. Protective film strenght is already 83% with oil only being 40–50 ⁰C temperature. 100% film strenght is achieved when oil reaches 110 ⁰C and strenght maintained even to 140 ⁰C.

In comparison conventional oil film strenght is only 68% with 110 ⁰C oil temperature.

These exclusive properties, protective film strengh, of Nanodrive oil are very important as it ensures a high levels of protection during engine start up/warming up until engine reaches normal operational temperature. Also it worth noting, that most of engines used in motorsport operate at temperatures above 100⁰C or prolonged times, Nanodrive oils ensure that protection film strengh levels at these high level operating temperatures are maintained.

Another important property of the Nanodrive oils is reduction of friction coefficient under high operational temperatures. Above tests proved, that using Nano additives, friction coefficient started decrease, when engine reached 90 ⁰C and above operational temperatures. In comparison with conventional oil, friction coefficient reduced by 50% and above.

This property enable engine to operate much more efficient and release more power to drive train.

Comparison o Friction Coefficients

Additional tests

Millers Oils in addition to the above tests also undertook similar test to compare same viscosity engine oils of the other manufacturer. Fot this particular test Millers Oils CFS 10w50 NT engine oils was used and same 10w50 viscosity oil from other manuacturer.

Other properties related to Nanodrive Engine Oils

In comparison with normal CFS range oils, CFS NT oils appear of much more darker colour. This due to Nano additives used in these oils.

We would like to highlight that exlusive friction coefficient reduction usually appears once engine oil reached working temperatures of 100 ⁰C and above. Please note engine oil require to reach 100 ⁰C and above only once for friction reduction properties to appear in full. Afterwards friction coefficient reduction properties will remain low inrespectavely of the engine oil temperature through out the life of the engine oil.

Another of the properties of the Nanodrive engine oils is strenght of the protective film on metal surfaces. Nanodrive oils provide 90-98% oil film strength at 40-50 ⁰C operating temperatures, when competitors oil only achieved 60-70% oil film strength under same conditions.

It is that due to Nano particles in the engine oil, internal surfaces of the engine become covered in fine oily film, which remains on the metal surfaces.

We would like to advice, that using Nanodrive engine oil, it is not advisable to use engine flush fluids between oil changes. These will only remove already built protective film on the surfaces and build up of the protective film will require start again on clean metal surfaces. By only draining used Nanodrive engine oil and replacing it with fresh one, the protective film will only require to built further protective layers, therefore ensuring strong and continuous protective film on static and dynamic internal parts of engine.

Other factors

It was reported/noted that when using Nanodrive engine oil, oil could become relatevely dark colour ater a couple of hundred kilometers or a few hours of engine running.

Please be assured, this is normal process associated with most of modern synthetic oils. Dark colour of engine oil – is the sign that oil doing its job of keeping soot, dirt and other combustion contminants in suspension to be carried to the filter or removed from the engine when oil is changed. This is happening mainly to detergents in the modern oils, which help to disperse the tiny particles that can result in engine sludge and holding them in suspension in the oil so that they can not build up. That is why oil appears darker, but this in no way impedes the oil from performing its normal unctions of lubricating and protecting metal surfaces inside engine. If very tiny particles of dirt, soot and other contaminants to be filtered by oil filter, this will result is very low flow of oil throught oil filter which will result in lack of lubrication and eventually mechanical failure. Therefore oil filter designed to retain only particles to certain size, all smaller ones become suspended in engine oil.

For the above factors and Nanodrive engine oil properies in forming very strong protective film on metal surfaces it could be noted upon stripping engine that majority of parts are covered in dark oil film – this normal appearance when using Nanodrive engine oils. If the internal engine surfaces are found clean or oil found of clear colour (similar to fresh oil colour), it could be the sign that oil does not performs its main functions – formation of protective film, which gets removed-washed away from surfaces resulting in direct metal parts contact and dispensation of soot, dirt and combustion contaminants.

Key factors determing the quality of th used engine oil are the levels of various elements in it. These usually represented by ppm (pareticles per million) values. Leveles of wear metals and remaining additives in used oil will determine oil suitability for futher use, levels of viscosity remaining and could also indicate if specific internal engine components started to wear and could lead to future mechanical failures.

Please see below a typical CFS 10w60 NT oil analysis. Oil was used in N Group specification Mitsubishi Lancer Evolution IX. Sample provided after 300km of SS and engine covered 800km following full re-build. Oil sample supplied to the lab was quite dark in colour.

Sample Anaylisis Conclusion

Notes: Sample ID 6056

Original 10w60 values

Viscosity at 100 degrees C 24.4 cSt

Density 0.8700

Used Values

Viscosity at 100 degrees C 22 cSt

Density 0.8671

Both these values represent a satisfactory response for this type of product after use.

The oil as examined in our opinion was found to be in good condition with no evidence of

oxidation or additive depletion identified. Wear Metal Analysis reveals satisfactory

additive levels of Ca, Zn, Mg, B & Mo. All other levels are totally satisfactory.

Please note that for all our customers using Millers Oils products we offer an opportunity to have oil samples analysed at Millers Oils Research & Development Centre in United Kingdom. Would you like to use this service, please contact our partners EAMV Motorsport, who will provide you with 100ml jar for sample and could assist with taking oil sample from your engine or transmission.

We hope all information and explanation above enabled you to understand the Nanodrive engine oil key properties and benefits. Would you have any further questions, please feel free to contact us with your queries-questions by e-mailing us at: informacija@millers-oils.lt or alternatively contacting our Motorsport range retailers in Lithuania EAMV Motorsport at: manager@eamvmotorsport.com.

Millers Oils Lietuva

Categories:

News